It seems like an eternity that I’ve driven my Z32, honestly this build started from what seemed to be a great idea at the time from was supposed to have been a quick and easy SR20 build that turned into what a few friends and I call, “the slippery slope”. When I stripped the old S14 engine down to the bare bones and inspected everything I found the cylinder head to be far outside of specs, too far for me to comfortably use in a competition setting. I set out to try and find another RWD SR20 head within a reasonable price but after months and months of no luck I refused to spend top dollar on a head or block and be left again with a standard SR20. Looking back I probably should of done that s I would have much more seat time now, unfortunately that is not the case and thus here we are, the beginning of project VVL SRZ32.

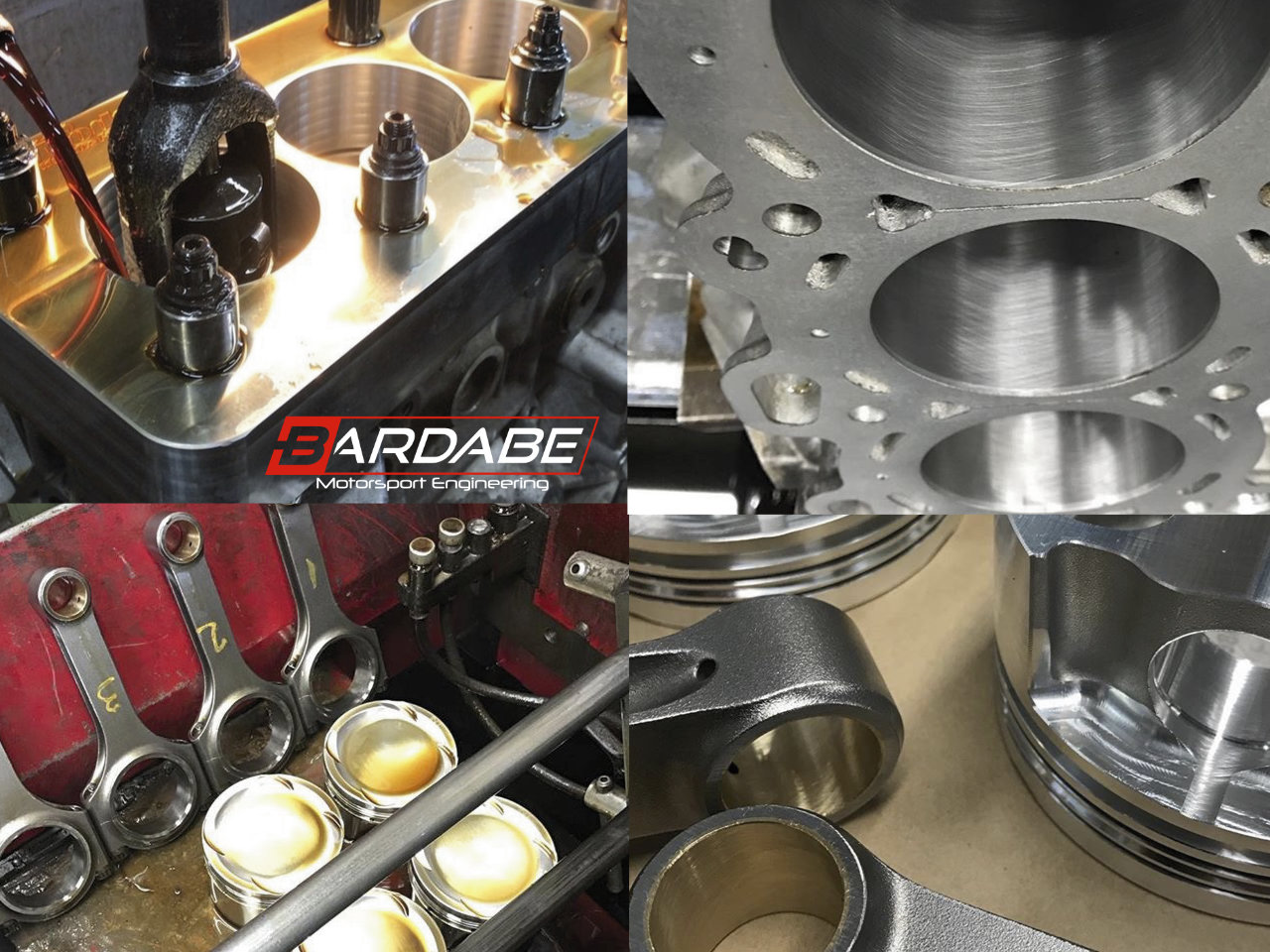

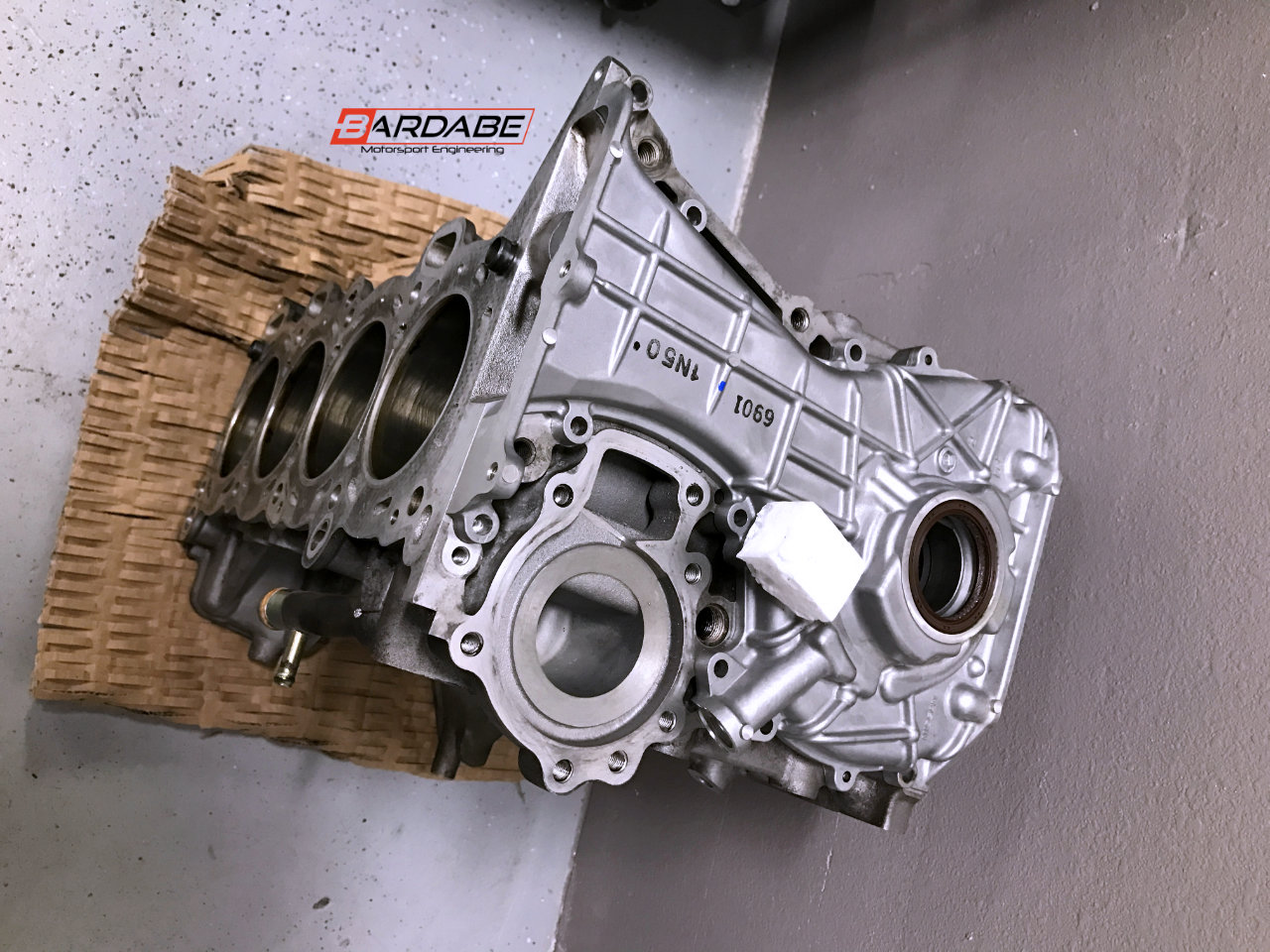

Being that I was now building a VVL Turbo engine, pistons with valve reliefs are necessary. Nick from JE Pistons and K1 Technologies provided me with pistons, rods, upgraded wrist pins & a head gasket to hold down all the power. With a proper rotating assembly I did a few modifications to the S14 65F block in order to be able to use the SR16VE N1 oil pump and delivered the hard parts to my machine shop, Arlington Machine in Riverside California. Aaron did the rest of the modifications to the block for me which included drilling and tapping the rear oil drain on the RWD head that is not used with the P11 / P12 cylinder heads.

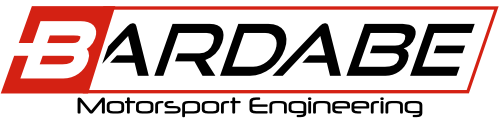

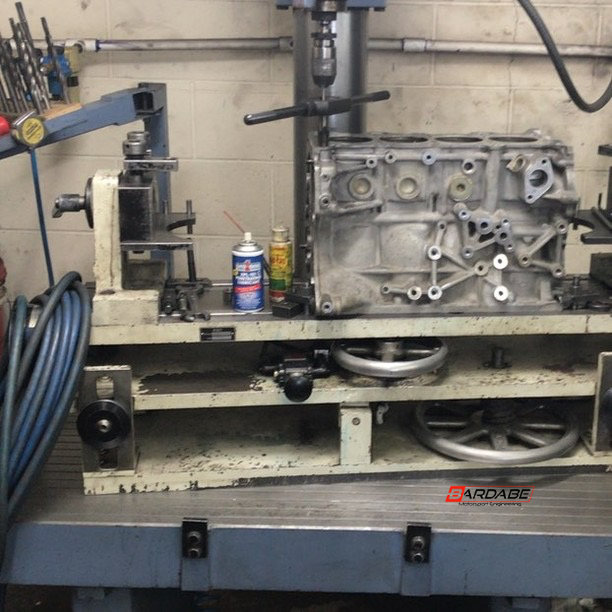

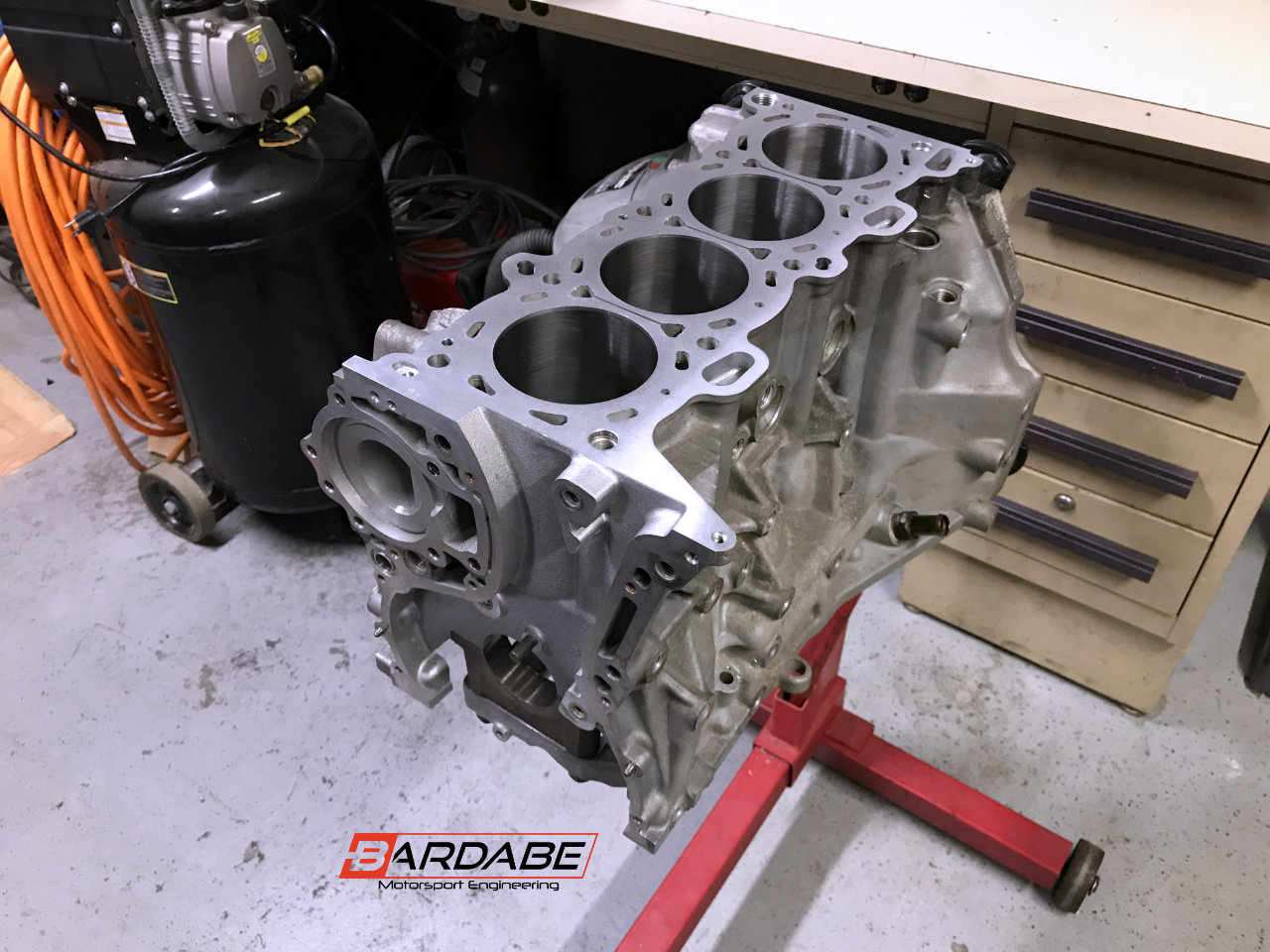

With all parts dropped off at Arlington machine Aaron Resurfaced the deck surface and went to town. Bored, torque plate honed, line honed, balanced, re-sized rod ends, piston wrist pin holes, and set other specific hard parts to our own specification. This is of course after checking block and crank for any cracks or imperfections that could cause an issue later. All in all the process in the rotating assembly was very standard for my engines, nothing I consider special but work that must be done for a reliable competition engine.

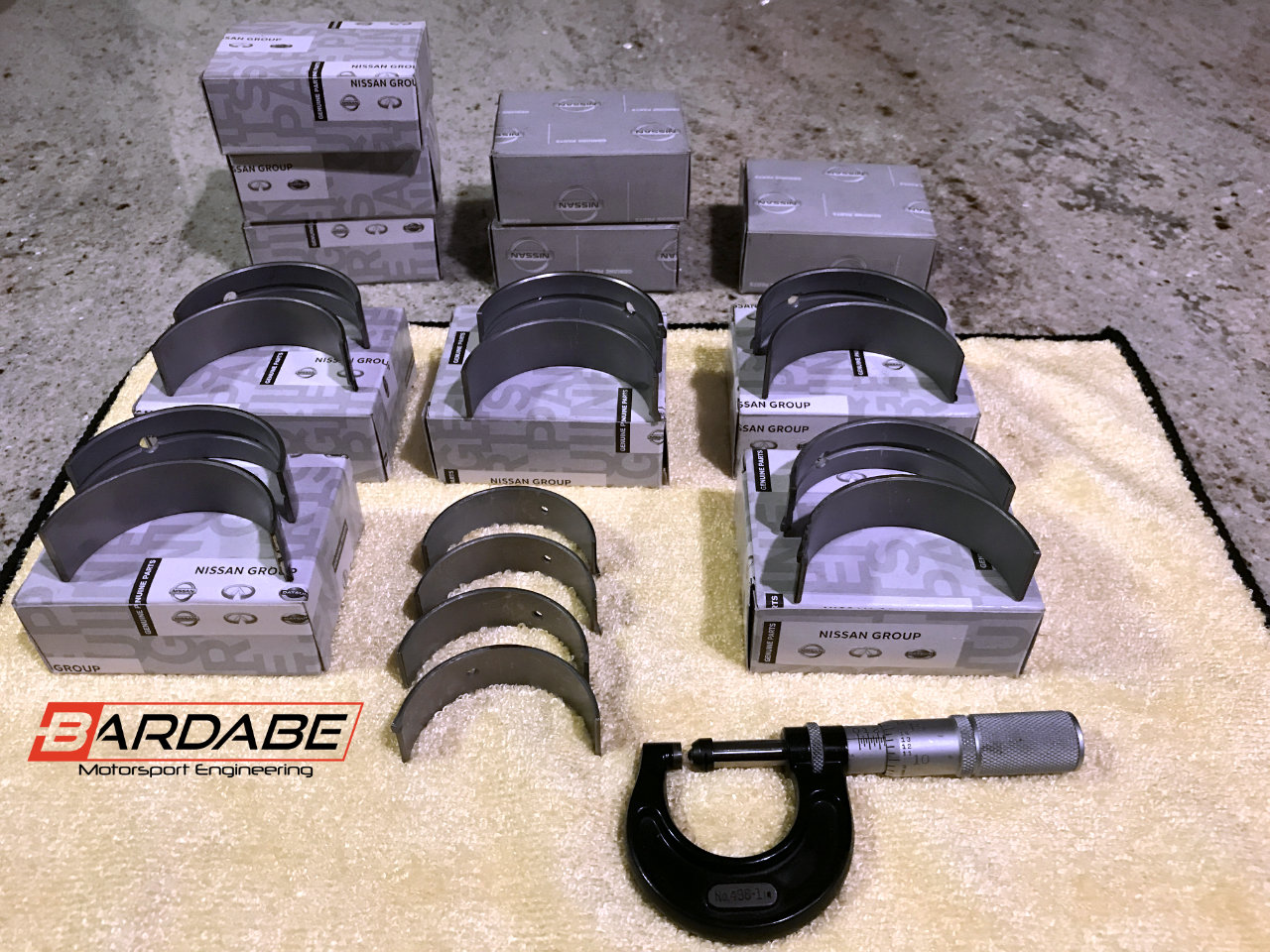

With the engine back in my Garage, I de-burred and blue printed the entire assembly. After blue printing I measured all of my inventory of Nissan bearings I have on my shelf, order a few more and select the appropriate thickness bearings to get me the desired clearances. it’s an incredibly tedious and long process. Everything has to be measured down to .0001″ tolerances and documented. I’m going to say this is the most crucial part of an engine build as any mistakes here if not caught during the double check process will lead to a quick and painful engine failure. These are some of the tools I use for measuring a rotating assembly.

With all the measurements done I sent all of my components along with the cylinder block to WPC Treatment in Torrance California to have every moving component treated for durability, block is to hang out until the cylinder head is ready to meet it’s new friend.

Sources:

JE Pistons

K1 Technologies

WPC Treatment

Arlington Machine